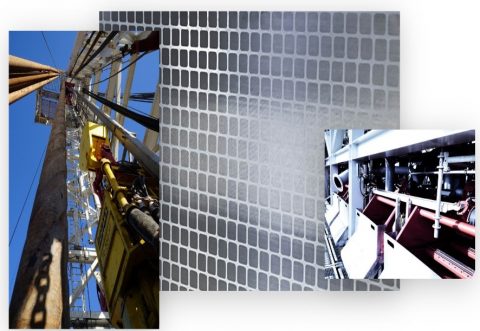

Shale shaker replacement screens are the most crucial part of a shale shaker. The main objective of these screens is to separate the liquid part of the drilling sap from unwanted solid material. The material used to manufacture the screen is woven metal. On insertion in the shale shaker, it appears like a mesh screen.

When a shale shaker generates the drilling fluid, shale shaker screens start doing their work of filtration. The solid particles get trap on the screen and result in the production of desirable fluid. Shale shaker replacement screens from various sources can fit a wide variety of shale shakers regardless of their sizes and dimensions. Here are five factors which depict the best sources of shale shaker replacement screens:

1: Screen Frame

The frame of the shale shaker replacement screens is made up of a variety of materials such as plastic style composites, flat steel sheets, and square steel tubing. A good quality screen contains a less wide frame, which helps in increasing the surface area of the screen available for work. A screen frame provides maximum support and rigidity to the frame.

2: Screen Mesh

A screen mesh is very thin, but a strong metal sheet. High-quality screen mesh always contains rectangular openings in it, which help in increasing the conductance of the screen. To maximize screen vitality, multiple layers of the mesh are added to it, which also helps in trapping the finest particles.

3: Binding Agent

The binding agent is an adhesive that is used to bind the mesh to the screen frame. A high-quality binding agent is used in a good quality shale shaker screen, which can tolerate a wide variety of thermal temperatures, strong vibrations, abrasive cuttings, and corrosive fluids.

4: Drier Cuttings

High-quality shaker replacement screens are capable of minimizing fluid loss by jolting very thin layers of drilling fluid over the screen. This not only facilitates faster drying but also enables the screening of 1 to 2 API sized particles. This helps in saving time and increasing productivity.

4: Finer Separations

Shale shaker screens from a good source provide finer separations of particles. It helps in enhancing the overall permeability of the screen. More vibrations and gravity allow more fluid to pass through the screen. Shale shaker screens are capable of making microscopic separations up to the size of 40 microns.

5: Increased Shaker Capacity

Great quality shale shaker screens increase the drilling capacity of the screen by increasing the API non-blanked area of the screen. This facilitates in increasing fluid handling capacity and also increases the functional screen area.

The Bottom Line

Shale shaker replacement screens that come from a good source are typically replaceable. They can fit in almost every model of shale shaker, which can eliminate the need to replace existing oil drilling equipment.

Good quality shale shaker screens are made by U.S. Patented technology. There long life, durability, wide range of designs, and customizability provide outstanding separation for materials.