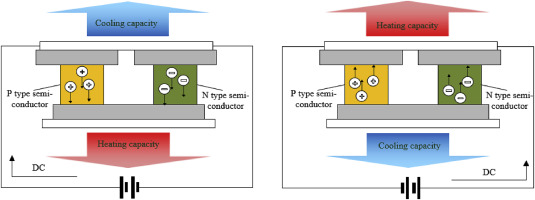

When you choose the right thermal processing equipment, it will impact your production line for a long time. It’s not just about the upfront cost of the machine, which is a lot of money, but also the long-term costs that need to be taken into account. Many of the devices used in factories can last for 20 or more years. The following are the top five things to think about when you choose a thermal processor and equipment like thermoelectric heat pump etc.

1. Drying range of temperatures –

From –580F (–500C) up to 54000F (30000C), thermal processing can be done. High temperatures are the only way to make metals and other materials used today. Some things are more important than others regarding food, drugs, and other consumer packaged goods, though.

2. It is essential to keep the temperature in check –

For many thermal processing applications, getting the temperature right is very important to the overall quality of the finished product. When precise heating isn’t needed, it can save time and money by being faster and more accurate. Most thermal processing methods use air or fluid (indirect) heating, which means that very few techniques can provide very controlled environments and the ability to quickly and quickly change the temperature.

3. Costs and how well things work –

Energy costs go down when you use the proper heating or cooling. Other things that can be just as important when it comes to efficiency are:

• The footprint of the machine. Thermal processing equipment that uses air drying usually has a bigger footprint and needs more space to keep people safe and avoid damage to other equipment in the area.

4. Throughput –

Every application has different needs for the number of materials used. It may seem evident that faster processing of more things is better, but that may not be the case in every case. For example, when more processing or packaging is needed, the maximum throughput may be limited by other things. The needs may be very few or very few in finish drying applications.

5. For certain types of materials, there are special rules –

Your thermal processing equipment (like a thermoelectric heat pump) should be made to meet the needs of only one type of application: yours. This article can’t cover every possible particular condition, but here are a few examples of special needs:

• Keep the taste, color, and nutritional value of food and ingredients the same.

• People who work with salty and corrosive things need contact surfaces to withstand corrosion.

Final Words…!!!

As with any other decision, it’s essential to look at your options and work with experts. Most manufacturers have testing facilities that you can use to determine how a machine will work with your specific materials; if you want to get the best out of your processing line, run tests in a wide range of conditions.