Introduction

In the world of engineering and manufacturing, precision and accuracy are of utmost importance. BSP (British Standard Pipe) thread gauges play a vital role in ensuring the correct fit and functionality of threaded components. This comprehensive guide aims to provide an in-depth understanding of BSP thread gauges, their types, and various applications in different industries.

What are BSP Thread Gauges?

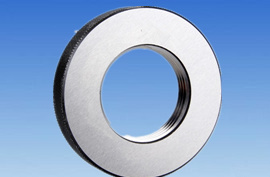

BSP thread gauges are precision tools used to measure and calibrate threads, specifically British Standard Pipe threads. These gauges are essential for ensuring the proper fit and alignment of threaded components, which is crucial for the integrity and functionality of various mechanical systems.

BSP Thread Gauge Design

BSP thread gauges typically consist of a male and female gauge. The male gauge has an externally threaded section, while the female gauge has an internally threaded section. When these gauges fit together perfectly, it indicates that the threads are within the specified tolerances.

Importance of BSP Thread Gauges

Accurate and consistent threading is essential in numerous industries, such as plumbing, automotive, and manufacturing. BSP thread gauges play a vital role in achieving this accuracy, as they ensure that threaded components fit securely and function correctly.

Types of BSP Thread Gauges

There are two main types of BSP thread gauges:

BSP Parallel Thread Gauges (BSPP)

BSPP gauges have a parallel thread profile and are commonly used in applications where a watertight seal is required, such as plumbing fittings and hydraulic systems.

BSP Tapered Thread Gauges (BSPT)

BSPT gauges have a tapering thread profile and are suitable for applications where a tight seal is needed, such as in gas connections and pneumatic systems.

BSP Thread Gauge Standards

To maintain uniformity and compatibility, BSP thread gauges adhere to specific standards:

BS 84:1956

This standard defines the thread dimensions and tolerances for BSP pipe threads.

BS 21:1985

This standard covers the requirements for taper external and internal threads of pipe threads.

ISO 228-1:2000

ISO 228-1 standardizes the requirements for BSP parallel and taper internal screw threads.

Understanding BSP Thread Gauges

To make the most of BSP thread gauges, it’s essential to understand their key components:

Thread Profile and Angle

The BSP thread profile is based on a 55-degree angle, commonly known as the Whitworth thread form.

Thread Crest and Root

The crest is the topmost part of the thread, while the root is the bottommost part.

Thread Flanks

The flanks are the sides of the thread that connect the crest and root.

Applications of BSP Thread Gauges

BSP thread gauges find extensive use in various industries:

Plumbing and Pipework

In plumbing applications, BSP thread gauges ensure proper fittings, preventing leaks and water damage.

Automotive Industry

BSP thread gauges play a crucial role in the automotive sector, where precision is essential for safety and performance.

Manufacturing and Machinery

In manufacturing processes, BSP thread gauges ensure interchangeability of components and smooth assembly.

Selecting the Right BSP Thread Gauge

Choosing the appropriate thread gauge requires considering several factors:

Consideration Factors

Factors like thread size, pitch, and type of fitting determine the right gauge.

Measuring and Calibration

Accurate measurements and regular calibration are vital to the effectiveness of BSP thread gauges.

Proper Maintenance of BSP Thread Gauges

To ensure longevity and accuracy, proper maintenance is necessary:

Cleaning and Storage

Regularly cleaning and storing gauges correctly prevent damage and contamination.

Regular Calibration

Regular calibration checks maintain the accuracy of the thread gauges.

Common Challenges and Troubleshooting

Identifying and addressing challenges associated with thread gauges:

Thread Gauges Wear and Tear

Frequent usage can lead to wear and tear of the gauges, affecting accuracy.

Incorrect Measurements

Incorrect handling or calibration can result in inaccurate measurements.

Benefits of Using BSP Thread Gauges

Using BSP thread gauges offers several advantages:

Ensuring Interchangeability

BSP thread gauges guarantee that components from different manufacturers are interchangeable.

Enhanced Product Performance

Precise threading leads to enhanced product performance and reliability.

Safety Precautions When Using BSP Thread Gauges

Safety should be a priority when working with thread gauges:

Protective Gear

Using appropriate protective gear prevents accidents and injuries.

Handling and Storage

Proper handling and storage of thread gauges minimize damage and ensure accuracy.

Conclusion

BSP thread gauges are indispensable tools in the world of engineering and manufacturing. Understanding their types, applications, and proper usage is crucial for ensuring precise and accurate threaded components. By adhering to standards, performing regular maintenance, and following safety precautions, professionals can make the most of BSP thread gauges and improve the quality and performance of their products.