Maintaining optimal temperature levels within infrastructures is crucial for ensuring the longevity and efficiency of various systems and components. In this regard, infrared thermography is an invaluable asset, offering a non-invasive and highly effective method for monitoring and managing temperature-related issues.

AGI’s thermography services offer a cost-effective and non-destructive method for detecting temperature-related issues, safeguarding your infrastructure against potential disruptions and costly repairs.

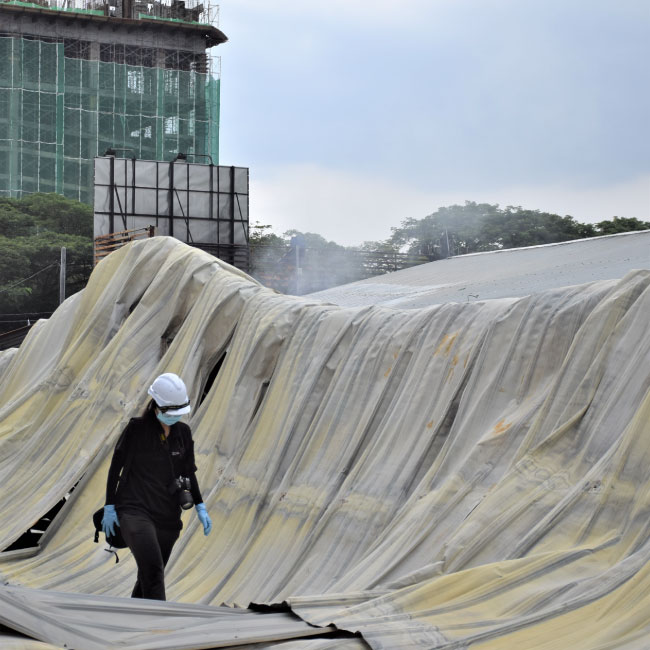

Let’s explore the role of this advanced technology in maintaining infrastructure temperature and explore AGI’s infrared thermography(IRT) service in Malaysia.

Understanding Infrared Thermography

Infrared thermography, also known as thermal imaging, leverages infrared radiation emitted by objects to generate visual representations of their temperature distributions. By utilizing specialized equipment capable of capturing these thermal images, maintenance professionals can identify abnormalities indicative of potential malfunctions or inefficiencies within various systems and components.

Applications in Electrical Systems

One of the primary domains where thermography excels is in the inspection of electrical systems. Through thermal imaging, technicians can pinpoint areas of excessive heat, which may signify loose connections, overloaded circuits, or faulty components. Identifying these issues proactively enables timely interventions, minimizing the risk of electrical failures, fires, and downtime.

Mechanical Equipment Inspection

In addition to electrical systems, IRT finds extensive utility in the inspection of mechanical equipment. By detecting anomalies in temperature distribution, such as overheating bearings or misaligned components, technicians can preemptively address potential failures, thereby extending equipment lifespan and optimizing operational efficiency.

The Process of Infrared Thermography

Data Acquisition

The first step in an IRT inspection involves the acquisition of thermal data. Highly sensitive infrared cameras are employed to capture thermal images of the target objects or systems, revealing temperature differentials that may indicate underlying issues.

Analysis and Interpretation

Once the thermal data is acquired, it undergoes meticulous analysis and interpretation by trained professionals. Through careful examination of thermal patterns and anomalies, technicians can diagnose potential problems and formulate appropriate corrective actions.

Reporting and Recommendations

Following the analysis, a detailed report is generated, outlining the findings of the IRT inspection. This report typically includes thermal images, temperature measurements, identified issues, and recommendations for remedial measures, facilitating informed decision-making by stakeholders.

Benefits

Early Detection of Issues

Perhaps the most significant advantage of IRT is its ability to detect issues at their nascent stages. By identifying anomalies before they manifest as visible defects or failures, infrared inspections enable proactive maintenance interventions, minimizing downtime and costly repairs.

Non-Destructive Testing

Unlike traditional diagnostic methods that may require invasive procedures or the disassembly of equipment, IRT is non-destructive. This means that inspections can be conducted without causing any disruption to operations, preserving the integrity of assets and minimizing downtime.

Cost Savings

While investing in regular thermography inspections incurs upfront costs, the long-term savings they generate far outweigh these expenses. By preventing catastrophic failures, reducing energy consumption through early detection of inefficiencies, and extending equipment lifespan, infrared thermography delivers substantial cost savings over time.

Industries Benefiting from Infrared Thermography

Manufacturing

In the manufacturing sector, where downtime can translate to significant revenue losses, thermography plays a pivotal role in maintaining operational continuity. By proactively identifying potential equipment failures, manufacturers can schedule maintenance activities strategically, optimizing production efficiency and minimizing disruptions.

Facilities Management

Facilities managers rely on IRT to ensure the reliability and safety of building systems, including HVAC, electrical, and plumbing infrastructure. By conducting routine thermal inspections, facility maintenance teams can detect issues such as insulation deficiencies, water leaks, or electrical faults, mitigating risks and preserving asset value.

Energy Sector

In the energy sector, where critical infrastructure such as power plants and substations is subject to rigorous operational demands, the implementation of thermography is indispensable. By monitoring the thermal performance of electrical components, transformers, and switchgear, energy companies can prevent costly outages and enhance grid reliability.

Overall, Infrared thermography is a cornerstone of modern maintenance practices, offering a proactive approach to asset management that mitigates risks, reduces downtime, and optimizes operational efficiency. By harnessing the power of thermal imaging technology, organizations across diverse industries can safeguard their investments, enhance safety, and achieve sustainable long-term success.

Contact AGI for expert infrared thermography services in Malaysia, providing comprehensive inspections, detailed reports, and actionable recommendations to ensure the optimal performance and longevity of your infrastructure.